Introduction

Propylparaben Production Process with Cost Analysis

Propylparaben, a commonly used preservative in the cosmetic, pharmaceutical, and food industries, plays a vital role in ensuring product longevity and safety. Understanding the production process and associated costs is essential for stakeholders in these industries. This press release provides a detailed overview of the propylparaben production process, encompassing market drivers, raw material requirements, costs, and key process information. Our aim is to offer a thorough analysis that supports informed decision-making and strategic planning.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/propylparaben/request-sample

Procurement Resource Assessment of the Propylparaben Production Process

Procurement Resource provides an in-depth assessment of the propylparaben production process, leveraging extensive market research and cost analysis to deliver valuable insights. Our evaluation covers every stage of the production process, from the synthesis of raw materials to the final product. By examining critical factors such as raw material availability, technological advancements, and market trends, we equip stakeholders with actionable intelligence to optimize their operations and strategic initiatives.

Understanding Propylparaben

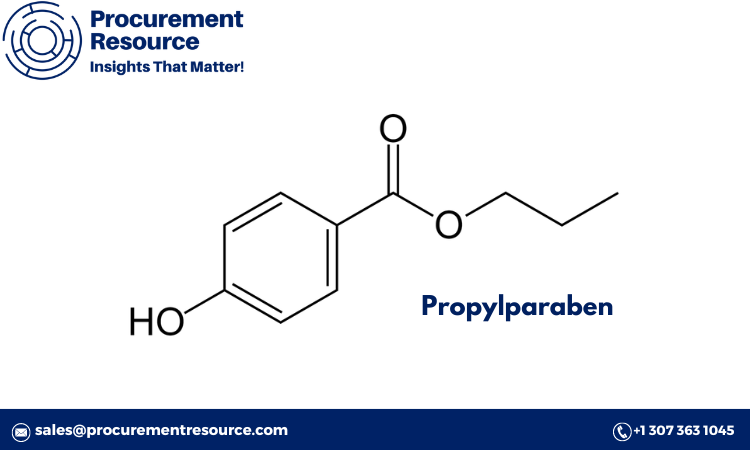

Propylparaben, chemically known as propyl p-hydroxybenzoate, is a member of the paraben family, widely recognized for its preservative properties. It is extensively used in cosmetics, pharmaceuticals, and food products to prevent microbial growth and extend shelf life. The synthesis of propylparaben involves the esterification of p-hydroxybenzoic acid with propanol, followed by purification and crystallization processes to achieve high purity.

The production of propylparaben involves several steps:

-

Esterification: p-Hydroxybenzoic acid reacts with propanol in the presence of a catalyst, typically sulfuric acid or p-toluenesulfonic acid, to form propylparaben.

-

Neutralization: The reaction mixture is neutralized to remove any remaining acidic components, ensuring the stability of the product.

-

Purification: The crude propylparaben undergoes purification processes such as recrystallization or distillation to remove impurities and achieve the desired purity level.

-

Drying and Packaging: The purified propylparaben is dried to remove any residual solvents and then packaged for distribution.

Market Drivers

Several key market drivers influence the propylparaben industry, affecting production volumes, pricing, and demand. These drivers include:

-

Consumer Demand for Preservatives: The growing demand for cosmetics, personal care products, and processed foods drives the need for effective preservatives like propylparaben to ensure product safety and longevity.

-

Regulatory Standards: Regulatory standards and guidelines established by agencies such as the FDA and European Commission impact the use of preservatives in various products. Compliance with these regulations drives the demand for high-quality propylparaben.

-

Technological Advancements: Innovations in production technologies enhance the efficiency and cost-effectiveness of propylparaben synthesis, influencing market dynamics.

-

Product Formulation Trends: Trends in product formulation, including the shift towards more natural and organic ingredients, impact the use of synthetic preservatives like propylparaben. However, its effectiveness and cost-efficiency ensure continued demand.

-

Global Population Growth: Increasing global population and rising disposable incomes contribute to the demand for consumer products, including cosmetics and processed foods, thereby driving the demand for propylparaben.

Raw Materials Requirements

The production of propylparaben requires specific raw materials to ensure high-quality output. Key raw materials include:

-

p-Hydroxybenzoic Acid: This is the primary raw material used in the esterification process to produce propylparaben.

-

Propanol: An alcohol used to esterify p-hydroxybenzoic acid, propanol is essential for the synthesis of propylparaben.

-

Catalysts: Acidic catalysts like sulfuric acid or p-toluenesulfonic acid facilitate the esterification reaction, ensuring efficient production.

-

Neutralizing Agents: These are used to neutralize the reaction mixture, typically bases like sodium hydroxide or potassium hydroxide.

Costs and Key Process Information

Understanding the costs and key process information is crucial for optimizing propylparaben production and achieving cost efficiency. Key cost components include:

-

Raw Material Costs: The cost of p-hydroxybenzoic acid, propanol, and catalysts are significant contributors to the overall production cost. Fluctuations in the prices of these raw materials can impact the cost structure.

-

Energy Costs: The energy required for heating, cooling, and purification processes is a major cost factor. Implementing energy-efficient technologies can help reduce these expenses.

-

Labor Costs: Skilled labor is required to manage the production process, from synthesis to purification. Automation and process optimization can improve productivity and reduce labor costs.

-

Equipment and Maintenance Costs: The cost of equipment used in the esterification, purification, and drying processes, along with regular maintenance expenses, contribute to the overall production cost.

Key process information includes:

-

Esterification Efficiency: Optimizing the esterification reaction to maximize yield and minimize by-products is crucial for cost-effective production.

-

Purification Techniques: Advanced purification techniques, such as recrystallization and distillation, ensure high product purity and quality, impacting market acceptance and regulatory compliance.

-

Regulatory Compliance: Adhering to regulatory standards and guidelines is essential for ensuring the safety and efficacy of propylparaben, influencing its marketability.

Looking for an Exhaustive and Personalized Report?

If you are looking for an exhaustive and personalized report that could significantly substantiate your business, Procurement Resource offers customized reports tailored to your specific needs. Our reports provide detailed market insights, cost analysis, and strategic recommendations to help you navigate the complexities of the propylparaben market. Whether you are a producer, investor, or industry stakeholder, our comprehensive reports offer valuable information to support your business decisions and optimize your operations.

Conclusion

The propylparaben production process is a complex and multifaceted industry, influenced by various factors such as consumer demand, regulatory standards, technological advancements, and global market trends. Understanding the intricacies of this process, along with its associated costs, is crucial for stakeholders across the supply chain. Procurement Resource provides a detailed and comprehensive analysis of the propylparaben production process, offering valuable insights and strategic recommendations to help businesses navigate this dynamic industry. By leveraging our expertise and in-depth market research, stakeholders can make informed decisions, optimize production processes, and achieve cost efficiency in the competitive propylparaben market.

About Us:

Virginia Business Blueprint: How to Kickstart Your Entrepreneurial Journey

Virginia Business Blueprint: How to Kickstart Your Entrepreneurial Journey  The Role of Udyam Registration in Atmanirbhar Bharat Abhiyan

The Role of Udyam Registration in Atmanirbhar Bharat Abhiyan  Mango Costs in Pakistan 2024: A Total Diagram

Mango Costs in Pakistan 2024: A Total Diagram  Why Professional Power Management Can Make or Break Your Event

Why Professional Power Management Can Make or Break Your Event  Experience The Thrill Of Zipline Dubai With Captain Dunes

Experience The Thrill Of Zipline Dubai With Captain Dunes  Exploring London’s Best Butcher Shops

Exploring London’s Best Butcher Shops  Enhance Your Shop Appeal with Sydney’s Best Carpentry Services

Enhance Your Shop Appeal with Sydney’s Best Carpentry Services  A Detailed Look at the Features of the LEGO Technic Mars Crew Exploration Rover

A Detailed Look at the Features of the LEGO Technic Mars Crew Exploration Rover